Industrial Measurement Excellence.

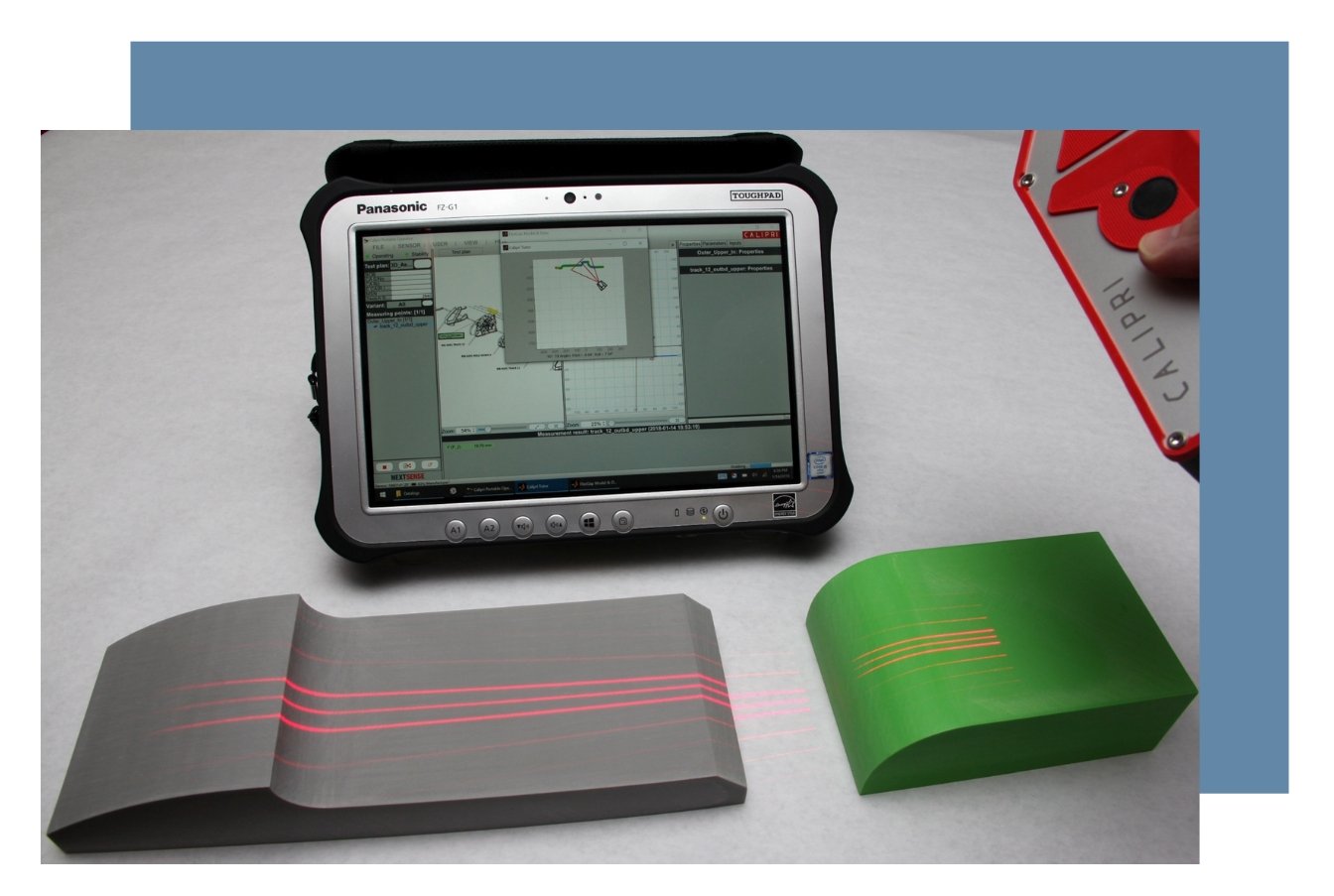

Our team helps to increase quality in automotive, aerospace and other industrial manufacturing, by integrating the CALIPRI measurement system, featuring unparalleled reliability and repeatability.

CALIPRI - by NEXTSENSE

CALIPRI systems used in

Automotive

Railway

Steel

Aerospace

Pipe Bevel

Green Energy

It's time to level-up your factory inspection

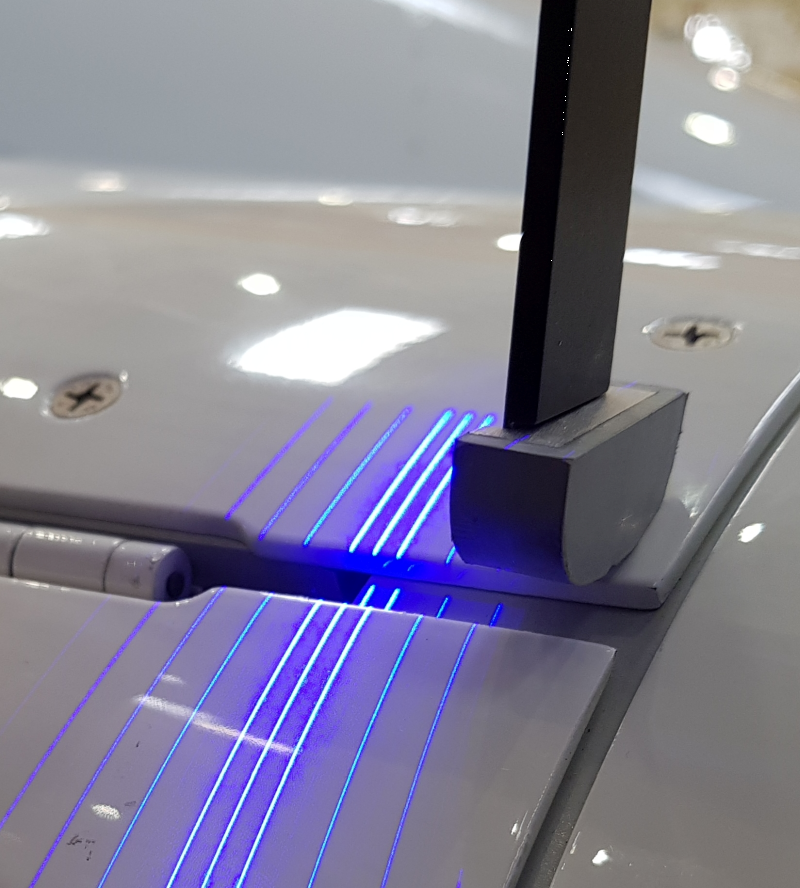

Automating gap and flush in the factory is a critical step to guaranteeing that only quality vehicles are delivered. CALIPRI CB20 can measure any gap, on any surface, every time.

Reliable Freehand measurements with laser precision

CALIPRI uses patented technology to introduce user independent measurements. This means that everyone measuring the same article with CALIPRI will get the same result. This increases production throughput and reduces costs.

Services offered

We can measure almost anything. You just need to try it.

Automotive

Hand held, in-line, offline, robotic gap and flush measurement for automotive manufacturing

Aerospace

Measurement of many aircraft parts (eg. skin gaps, door gaps, shim heights, spar gaps, steps, flushes, radii...)

Pipe bevels

Critical pipe bevel measurements to guarantee weld quality. Many different bevel profiles measured

Glue beads

Large scale glue bead cross section measurement - used in wind turbine blade manufacturing

Home appliances

Ensure your customers' clothes don't fall down the "sock gap" in washing machine manufacturing?

Training

Our experts help you to get the most our of your CALIPRI. The chances are, you are only using a very small percentage of its capability!

3 simple steps to check if we can measure your gap

Consultation

Describe the article to be measured and check against the physical limitations of the CALIPRI scanning system.

Site visit

Onsite trial to show proof of concept, to check configuration and parameters, full demonstration.

Proposal

Everything from device configuration, integration, training and support will be detailed.

User Independent Quality

To find out more, get in touch today and let's schedule a visit!

Get access to the CALIPRI members area with lots of useful information about the CALIPRI systems and how they work, videos, documents, links and much more. Just fill in the form and request access.

© 2022 Crontek SASU. All Rights Reserved.